TIF®040-12 è un cuscinetto di riempimento per spazi vuoti a base di gel siliconico morbido, formulato con una speciale miscela di riempitivi per fornire sia un'eccellente conduttività termica che una morbidezza superiore. Rispetto ai grassi termici convenzionali, TIF®040-12 ha una viscosità più elevata, che impedisce efficacemente la separazione del riempitivo dalla matrice siliconica e riduce la migrazione del riempitivo, contribuendo a mantenere prestazioni termiche costanti. Viene applicato in modo simile al grasso termico ed è adatto per l'erogazione commerciale o apparecchiature automatizzate. Le applicazioni tipiche includono microprocessori flip-chip, PPGAs, micro pacchetti BGA, pacchetti BGA, chip DSP, chip di silicio circolari, illuminazione a LED e altri componenti elettronici ad alta potenza.

Caratteristica

>Conduttività termica: 4,0 W/mK

>Morbido, compressione molto bassa

>Bassa impedenza termica

>Funzionamento automatico

>Affidabilità a lungo termine comprovata

Applicazione

>Dissipatore di calore e telaio

>Modulo retroilluminazione LED, illuminazione a LED

>Driver hardware ad alta velocità

>Micro heat pipe

>Controller motore veicolare

>Industria delle telecomunicazioni

>Apparecchiature di laboratorio automatiche per semiconduttori

>CPU

>Scheda video

>Scheda madre/scheda madre

>Notebook

| TIF®040-12 Proprietà tipiche |

| Proprietà |

Valore |

Metodo di prova |

| Colore |

Blu |

Visivo |

| Costruzione e composizione |

Materiale siliconico riempito di ceramica |

- |

| Portata (g/min) |

60 |

Metodo di prova Ziitek (siringa da 30 cc/orifizio da 2,5 mm/90 psi) |

| Densità (g/cc) |

3,2 g/cc |

ASTM D297 |

| Conduttività termica |

4,0 W/mK |

ASTM D5470 |

| Impedenza termica @10psi (℃.in²w) |

0,093 |

ASTM D5470 |

| Impedenza termica @50psi (℃.in²w) |

0,086 |

ASTM D5470 |

| Temperatura di esercizio consigliata |

-45 ~200°C |

Metodo di prova Ziitek |

| Resistenza dielettrica (V/mm) |

≥4000 |

ASTM D149 |

| Spessore della linea di legame (mm) |

0,20 |

Metodo di prova Ziitek |

| Valutazione di infiammabilità |

V-0 |

UL 94 |

| Durata di conservazione |

12 mesi |

- |

Specifiche del prodotto:

30 cc/pz, 98 pz/scatola; 300 cc/pz, 6 pz/scatola.

Imballaggio personalizzato disponibile per l'uso in automazione. Vi preghiamo di contattarci per la conferma.

Se desideri conoscere i nostri prodotti termici, visita il nostro sito web.

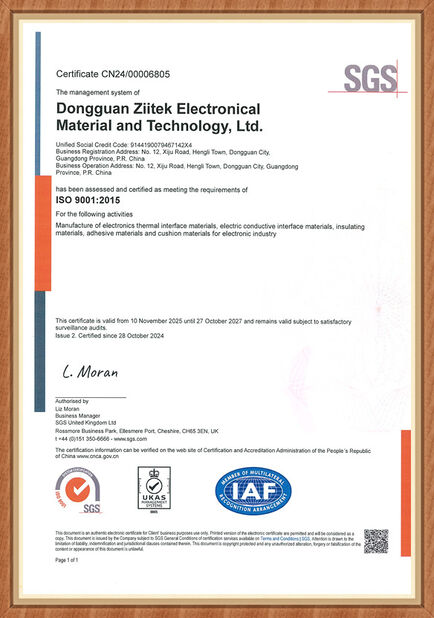

Profilo Aziendale

Ziitek Electronic Material e Technology Ltd.è dedicata allo sviluppo di soluzioni termiche composite e alla produzione di materiali di interfaccia termica superiori per un mercato competitivo. La nostra vasta esperienza ci consente di assistere al meglio i nostri clienti nel campo dell'ingegneria termica. Serviamo i clienti con prodotti personalizzati, linee di prodotti complete e produzione flessibile, il che ci rende il partner migliore e affidabile per te. Rendiamo il tuo design più perfetto!

FAQ:

D: Qual è il metodo di prova della conduttività termica indicato nella scheda tecnica?

R: Tutti i dati nella scheda sono effettivamente testati. Hot Disk e ASTM D5470 vengono utilizzati per testare la conduttività termica.

D: Come trovare la giusta conduttività termica per le mie applicazioni?

R: Dipende dai watt della sorgente di alimentazione, dalla capacità di dissipazione del calore. Ti preghiamo di comunicarci le tue applicazioni dettagliate e la potenza, in modo da poter consigliare i materiali termoconduttivi più adatti.

D: Accettate ordini personalizzati?

R: Sì, benvenuti agli ordini personalizzati. I nostri elementi personalizzati includono dimensioni, forma, colore e rivestimento su uno o due lati adesivi o rivestiti in fibra di vetro. Se desideri effettuare un ordine personalizzato, ti preghiamo gentilmente di offrire un disegno o di lasciare le informazioni sul tuo ordine personalizzato.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!