Spessori standard:

0,020" (0,51 mm) 0,030" (0,76 mm)

0,040" (1,02 mm) 0,050" (1,27 mm) 0,060" (1,52 mm)

0,070" (1,78 mm) 0,080" (2,03 mm) 0,090" (2,29 mm)

0,100" (2,54 mm) 0,110" (2,79 mm) 0,120" (3,05 mm)

0,130" (3,30 mm) 0,140" (3,56 mm) 0,150" (3,81 mm)

0,160" (4,06 mm) 0,170" (4,32 mm) 0,180" (4,57 mm)

0,190" (4,83 mm) 0,200" (5,08 mm)

Consultare la fabbrica per spessori alternativi.

Spessori del prodotto:

Spessori del prodotto: da 0,020 pollici a 0,200 pollici (da 0,5 mm a 5,0 mm)

Dimensioni del prodotto: 8" x 16" (203 mm x 406 mm)

È possibile fornire forme tagliate individualmente e spessori personalizzati. Vi preghiamo di contattarci per la conferma.

Il metodo di smaltimento sicuro non richiede una protezione speciale. La condizione di conservazione è a bassa temperatura e asciutta, lontano da fiamme libere e dalla luce solare diretta. Per il metodo dettagliato, fare riferimento alla scheda di sicurezza dei materiali del prodotto.

Dettagli dell'imballaggio e tempi di consegna

L'imballaggio del pad termico

1. con pellicola in PET o schiuma - per la protezione

2. utilizzare una scheda di carta per separare ogni strato

3. cartone per l'esportazione all'interno e all'esterno

4. soddisfare le esigenze dei clienti - personalizzato

Tempi di consegna:Quantità (pezzi): 5000

Tempo stimato (giorni): Da negoziare

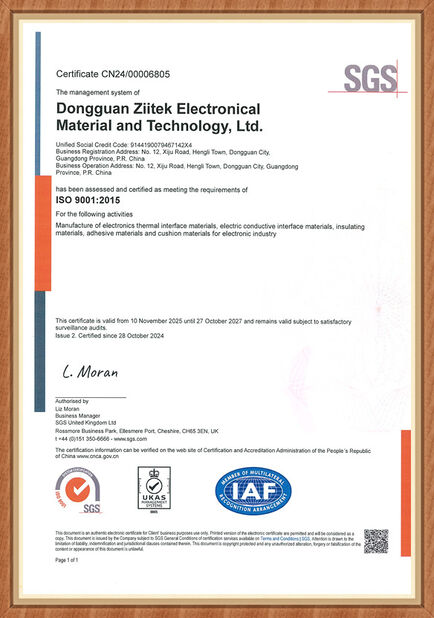

Profilo aziendale

Ziitek Electronic Material e Technology Ltd.è dedicata allo sviluppo di soluzioni termiche composite e alla produzione di materiali di interfaccia termica superiori per un mercato competitivo. La nostra vasta esperienza ci consente di assistere al meglio i nostri clienti nel campo dell'ingegneria termica. Serviamo i clienti con prodotti personalizzati prodotti, linee di prodotti complete e produzione flessibile, il che ci rende il partner migliore e affidabile per te. Rendiamo il tuo design più perfetto!

I nostri servizi

Servizio online: 12 ore, risposta alla richiesta entro il più veloce.

Orario di lavoro: 8:00 - 17:30, dal lunedì al sabato (UTC+8).

Personale ben addestrato ed esperto è a disposizione per rispondere a tutte le tue richieste, ovviamente in inglese.

Cartone per l'esportazione standard o contrassegnato con le informazioni del cliente o personalizzato.

Fornire campioni gratuiti

Servizio post-vendita: anche se i nostri prodotti hanno superato un'ispezione rigorosa, se si riscontra che le parti non funzionano bene, si prega di mostrarci la prova.

ti aiuteremo a gestirlo e ti daremo una soluzione soddisfacente.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!